At Bridge our committed consultancy team value the ability to sit down and understand our customers requirements, and incorporate them into a solution that will not only achieve them successfully, but will create a product that is manufactured from the correct material for your application, and is able to tolerate the correct conditions.

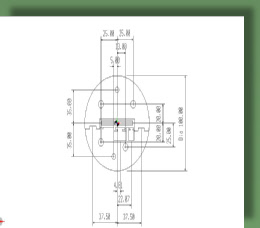

From the consultancy stage Bridge applies your requirements into our latest CAD product development facility, in which we are able to develop your product with meticulous detail. Our in-house tooling facility along with our skilled engineer’s are able to create the tooling required to produce a guaranteed quality product.

Plastic extrusion is a high volume manufacturing process in which raw plastic materials is melted and formed into a continuous profile. Thermoplastic material in the form of small pellets are fed from a top hopper into the barrel of the extruder. The material enters through the feed throat and comes into contact with the screw. The rotating screw forces the pellets along the barrel, which is heated to the desired melt temperature. At the front of the barrel the molten plastic leaves the screw through a breaker plate and enters the die. The die is what gives the product its profile. After passing through the die it must be now cooled by pulling the extrudate through the calibrators and a water bath.

Once the product has cooled it can be cut into lengths or spooled. This process is ideal for such applications as pipes, gaskets, curtain tracks, caravan surrounds, garden fence, posts and decking.

This type of extrusion utilises two or more extruders to melt and deliver a steady through put of different molten plastics to a single extrusion head which combines the material in a desired shape. This process allows a choice of rigid and flexible materials to be extruded together to form a composite profiles.

There are a variety of reasons a manufacture may choose Co-Extrusion. An example is in the mobile home and caravan industry, where Co-Extrusion is used to tailor the layers based on whether they are exposed to the weather or not. Usually a thin layer of compound that contains expensive weather resistant additives are extruded on the outside, while the inside is more suited for impact resistant and structural performance.

A wide range of shape, sizes and colours can be manufactured on our extrusion lines, most of which can produce Co-Extrusions examples can be seen in the gallery page of this website.